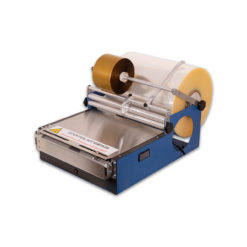

Industrial Cone Packer 300

- CAPACITY:300 pre-rolled cones per tray

- OUTPUT:100 filled cones in 1.5 minutes

- VARIABLE SPEED: Comes with variable speed controller for custom packing rates

- For Pallet Pricing, Please email at: [email protected]

Description

Industrial Cone Packer 300 (Pre-Roll Filling Machine):

CAPACITY: 300 pre-rolled cones per tray

OUTPUT: 100 filled cones in 1.5 minutes

ADJUSTABLE VOLUME WEIGHING: You can adjust our pre-roll machine to meter out a specific weight based on a volume using the included attachments.

SIZES: Made to specific cone-size and easily adjusted for other sizes with additional attachment

INDUSTRIAL: Made with stainless steel and aerospace-grade food-safe plastics

VARIABLE SPEED: Comes with variable speed controller for custom packing rates

WASTE & REWORK: Our pre-roll machine design lends to minimal waste & re-work required for incorrect weight. Our machine is made to a specific size creating a tight tolerance.

Video:

Video – Industrial Cone Packer 300 Machine

Industrial Cone Packer 300

Our industrial pre-roll machine packs 300 pre-rolled cones at a time and can work with any size pre-rolled cone. The loading tray is available in all sizes and can be swapped out within seconds. Made with stainless steel and heavy-duty food grade plastics, our commercial cone filling machine is easy to clean and extremely durable. Compared to other pre-roll machines & knockboxes, our industrial pre-roll machine comes with a variable speed controller this way you can fine-tune the exact packing rate. The free attachments included with the machine control the volume of product metered – this allows you to precisely fill cones to an accurate weight.

3X Capacity

Our pre-roll machine has capacity for 300 pre-rolled cones and 3-5X the capacity as other knockboxes or cone filling machine available on the market. Our industrial pre-roll machine works with all cone sizes – the cone loading tray comes in all standard sizes and custom sizes can be made!

Perfect Pack

Our industrial pre-rolled cone machine comes with a variable rate controller so you can fine-tune your packing process and achieve the perfect pre-roll every time. You know your flower best, so why let a pre-programmed machine tell you how to pack your flower! Take back control! Further enhance your packing process with one of our industrial grinders. It allows you to control your grinding particle size.

Industrial Build

Made with stainless steel and all food-grade aerospace plastics, our industrial cone filling machine is built like a tank. Tough design for maximum durability and interchangeable parts for easy maintenance. Pre-rolled cone loading trays come in all sizes and can be swapped out in seconds. Our pre-roll machine was developed with processors to work for processors!

About Line Packaging Supplies

At Line Packaging Supplies, we operate on a worldwide basis to provide our customers with container and packaging solutions for their needs. We supply glass, plastic, and metal packaging products to businesses and individuals. These include providing glass and plastic vials, glass bottles, metal containers, plastic and glass droppers, threaded test tubes, roll-on bottles, mason jars, pop-top bottles, bubble mailers, zip lock bags, pharmaceutical packaging and more! Most of our clients are small and medium-sized businesses or individuals. With bulk orders, wholesale pricing allows customers to considerably save up on costs, making it quite an affordable option.

Line Packaging Supplies has vast experience providing contract packers, dispensaries, pharmacies and retail shops with packaging solutions that help them succeed in the marketplace. No matter your size, positioning, or packaging needs, we provide outstanding service and bring you anything and everything from concept to commercialization. Our diversified offerings include vials, jars, bottles, exit bags and more with assorted closure systems that match your needs, be it rapid filling of orders behind the desk or secure ASTM and CPSC certified and tamper-evident packaging. We offer opaque child-resistant and tamper-evident containers that are FDA approved and certified BPA free, making them a top choice for the secure and discrete distribution of pharmaceuticals, flowers, concentrates, herb and edibles of all kinds. Discerning dispensaries also flock to our ASTM approved child resistant pre-roll and blunt tubes, which take advantage of a unique squeeze-top design to deter children while maintaining ease of use for adults. Our ASTM approved child resistant exit bags take the guesswork out of keeping up with complicated regulations by meeting the strictest state regulations.

Disclaimer: Our products and services are intended for pharmacies, clinics, laboratories, veterinaries and only legal medical growers – qualified patients, primary caregivers or coops or collectives – who cultivate edibles in compliance with the Compassionate Use Act (Proposition 215).

[sc_fs_multi_faq headline-0=”h2″ question-0=”How does your pre-roll machine / knockbox alternative work?” answer-0=”The basic operation of the Cone Packer 300 rely on a vibrating motor to shake the cones and pack the material down. The machine requires the user to place the cones into the individual slots, fill the material into the individual holes, release the material into the pre-rolled cones, and turn on the vibrating motor. The basic operation of most pre-roll filling machines such as the Futurola Knockbox consists of these steps.” image-0=”” headline-1=”h2″ question-1=”How does the output of your pre-roll machine compare with the Futurola Knockbox or other cone-filling machines?” answer-1=”The Futurola Knockbox states it can fill 100 pre-rolled cones in 2 minutes, we’ve seen on average that it takes users of our pre-roll machine approximately 5 minutes to fill 300 cones. About the same as the Futurola Knockbox. Other pre-roll machines may have a higher number of slots and therefore claim to be “faster” but that is a false statement. You may fill more material at once but that doesn’t change the fact you spent more time getting the machine ready for filling. On average you will end up spending about the same amount of time per cone. The true output of your pre-roll production line is not a function of how quickly does your machine fill cones instead it is a function of how quickly can you weigh, seal, and package your filled cones. Filling the cones is the easy step it is the manual process afterwards that will control how much finished product you have to sell. ” image-1=”” headline-2=”h2″ question-2=”How does the waste rate of your pre-roll machine compare with the Futurola Knockbox or other cone-filling machines?” answer-2=”As our pre-roll machine is made to a specific size cone the gap around the pre-rolled cone is extremely tight. The Futurola knockbox use one size machine to fit cones with a diameter between 11mm – 12.5mm – this means when you use smaller sized cones like the 84mm pre-rolled cones you get a lot more material falling around the pre-rolled cone. You will not be able to get an accurate weight measurements based on volume as the entire volume of material is not falling into the cone. The fact that our pre-roll machine is made to a specific cone size means that less material will fall around the cone regardless of what size you use. Further our pre-roll machine is designed with catchment tray to catch any material which doesn’t fall into the pre-rolled cones. The machine can also be place in a large tub or tray to further catch excess material.” image-2=”” headline-3=”h2″ question-3=”Does your pre-roll machine work with any brand of pre-rolled cone?” answer-3=”Yes, our pre-roll machine is made to order so it can be made to work with any sized pre-rolled cone. Our pre-roll machine is engineered to work with any size cone, so even if you want to pack party sized pre-rolled cones or you have a custom sized cone, our knockbox can be fitted to fill any sized cone. ” image-3=”” headline-4=”h2″ question-4=”What is multi-variable vibration control?” answer-4=”Compared to the Futurola knockbox, which only has a high and low vibration setting – our pre-roll machine is equipped with a multi-variable vibration control, which is operated on a dial, so you can hone in the perfect vibration setting for any strain or pack level. ” image-4=”” headline-5=”h2″ question-5=”What materials are used to make this pre-roll machine? What can I clean the pre-roll machine with?” answer-5=”All of the metal parts on the machine are made with food-grade stainless steel. All of the plastic parts are made from high-density, heavy-duty food grade plastics. It is safe to clean the machine with acetone or isopropyl alcohol. The machine disassembles with ease and all the nook/crannies are easily accessible for cleaning ” image-5=”” headline-6=”h2″ question-6=”How accurate is volume based weighing? Can I fill accurate weights with your pre-roll machine?” answer-6=”Volume based weighing can be accurate however it requires some trial-and-error to calibrate the machine to the correct weight. Most other pre-roll machines & knockboxes only allow you to meter one volume. Our pre-roll machine allows you to meter different volumes – this means you can optimize the volumes per strain of flower metering out an accurate weight into each pre-rolled cone. As long as your flower remains consistent from batch to batch and you meter the same volume you can accurately fill your pre-rolled cones ” image-6=”” count=”7″ html=”true” css_class=””]

Additional information

| Cone Size | 84mm Cones, 98mm slim Cones, 98mm Standard Cones, 109mm Cones, Custom Size (Include the details in the order comment or checkout page) |

|---|